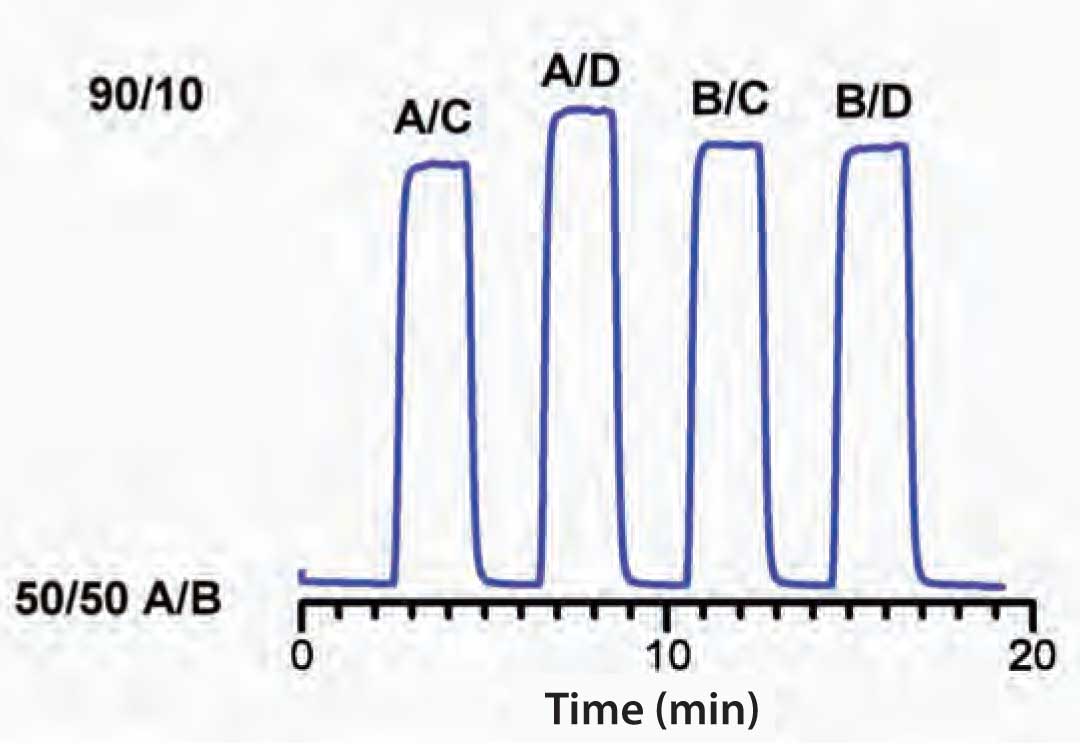

In the last instalment of HPLC Solutions (#74), we looked at the gradient proportioning valve (GPV) test as a tool to check for proper operation of the proportioning valves used to blend solvents in low-pressure-mixing HPLC systems. The test comprised steps between water and water-acetone mixtures, testing all possible combinations for the four (A, B, C, and D) solvents. If the steps or “peaks” in the resulting plot are within 5% of each other, the system is operating properly – usually the maximum difference between steps will be 1-2%. Let’s look now at an example where something goes wrong.

The GPV test was run and plot of Figure 1 resulted. You can see that the first two steps (A/C, A/D) differ by ≈12%, whereas C/B and C/D look the same. All four steps should be the same. Because solvent A is common for the two problem steps, I suspect that the A-solvent delivery system is the source of the problem. Most of us use the A-solvent line for water or buffer, rather than the organic solvent. The aqueous phase is more likely to grow bacteria than the organic phase, so the A-solvent’s inlet frit is more likely to become blocked, too. The next action that I would take is to check for a blocked frit by using a siphon test. Just disconnect the tubing at the inlet to the mixing manifold and see if solvent siphons freely through the tubing. I like to see 10 times as much solvent available by siphon action as will be needed by the pump. For example, if you normally operate at 1-2 mL/min, at least 20 mL/min should flow through the tubing by siphon action. If the solvent just drips out or doesn’t come out at all, remove the inlet frit in the reservoir and try the siphon again. If it works now, the frit is blocked – replace it. If the flow is still restricted, check for blockage in the tubing between the reservoir and the proportioning manifold. In the present example, the siphon test was performed and it passed easily, so we knew that the frit was not to blame for the poor proportioning.

Figure 1

Figure 1

When an abnormal GPV test is observed, as in Figure 1, and there are not restrictions to the mobile phase supply, the valve timing is likely to be out of calibration. Consult the maintenance manual for the system for instructions on adjustment of the mobile phase proportioning. Most systems have an adjustment in the software that allows for this. In the present case, the proportioning was adjusted several times, with improvements each time. Finally, the test was able to pass, but just barely, at about 4.8%. We were not happy with the results, so we replaced the entire mixing manifold and the test passed with ease.

The likely cause of this problem was a worn proportioning valve for solvent-A. For best operation, the valve response characteristics are matched at the factory, so the set of four valves have similar opening and closing times. Replacement of only one valve is difficult, because it is unlikely to match the other three. If we had to continue operation while waiting for parts, we could have switched to using one of the other reservoirs for the “A” solvent. For example, instead of running gradients from A to B, we could have run from C to B, not using the A-channel at all or just using it for flushing or other non-critical operations.

It is interesting to note that the problem shown here was found during a semi-annual performance qualification of the instrument. The HPLC system was apparently working properly – analytical results were consistent and quality-control samples passed easily – but there clearly is a problem with the proportioning system. By catching and correcting this problem before it began to degrade data quality or cause system shut-down, undesirable future problems were avoided. This is just one exampl

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com