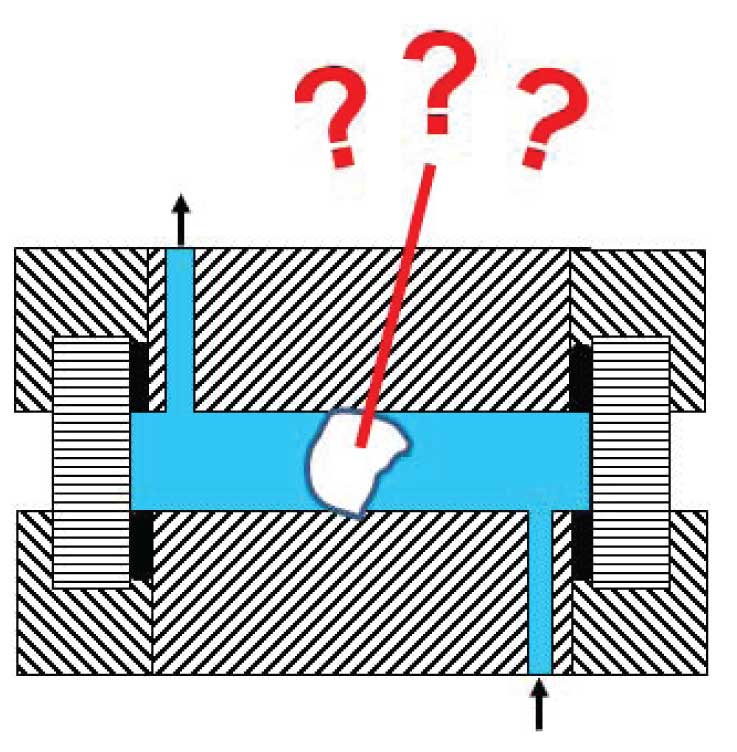

A reader recently asked, “The flow cell on my UV detector is completely blocked with some kind of white substance. I tried using a syringe to flush with water and with isopropanol, but neither was successful (and the process was very slow). The manufacturer of the detector says that I can get a cell service kit, but I’m a graduate student and can’t afford one. Do you have any ideas what is going on and how to fix the problem?”

There are only two sources for white solids in an HPLC system that I can think of: precipitated buffer or silica from the column. Before trying to clean up the flow cell, I would try to figure out the source of the solid. If you were using phosphate buffer, precipitation is a potential problem, especially if acetonitrile (ACN) is used as the organic component of the mobile phase and a high phosphate concentration is used. For example, phosphate forms a saturated solution at a concentration of only 10 mM in 80% ACN.

Silica could be leaking from the end of the column, but this is rarely a problem. If you have tried to reverse-flush a column that is not meant to be reverse-flushed, silica leakage could happen. For example, some 3 µm particle columns are packed with an 0.5 µm porosity frit at the outlet and a 2 µm frit at the inlet. Reversing such columns for a short time to back-flush usually is OK, but leaving them in the reverse direction for an extended time may allow fine particles to leak through the frit. If the end fitting were loose for some reason, silica could leak out, as well. Finally, if the pH of the mobile phase is >8, silica can dissolve, but I wouldn’t think that it would then precipitate in the flow cell.

How to fix it? If it is phosphate (or another buffer salt), carefully back-flushing the cell with warm water should eventually dissolve it, but be careful about using the HPLC pump to do this – the pressure may be too high and cause cell leakage. Removal of the flow cell and sonication may help to disrupt the particles and dissolve them more quickly. If the problem is silica-related, I think it is unlikely that you’ll ever dissolve it by flushing – it will require rebuilding or replacing the cell.

You are lucky if the cell can be rebuilt – some can’t be. Do you need a rebuild kit? Not necessarily, but you may have to find funds for this. The kit probably contains new windows and seals. If the old windows aren’t damaged, you may be able to carefully dismantle the cell, clean it, and reuse the seals. No guarantee on this, but I would probably try it, since there isn’t much to lose at this point. A final alternative might be to buy a used flow cell on e-Bay. It is amazing what you can find there!

Prevention? Be good to the column so you don’t operate under conditions where silica can leak out or dissolve. If it is buffer precipitation, avoid precipitating conditions. You can check for this by taking a test tube full of the organic solvent you are using and add buffer drop-wise. Then reverse this and add organic drop-wise to the buffer. If there is cloudiness when the drop contacts the bulk solvent, there is a potential for precipitation somewhere in the system. Reduce the buffer concentration or try pre-mixing the mobile phase to avoid this condition.

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com