In this article we cover the first part of an important and often neglected topic: ferrules.

Gas chromatography would not be a practical routine technique without ferrules – those necessary consumables that provide a pressure seal between the atmosphere and the gas flow path. Ferrules are used in junctions that can be disconnected and remade. Proper selection and use of ferrules ensures a reliable installation. Incorrect selection and/or implementation can cause enumerable problems and can affect the quality of analytical results.

All about Plumbing

At a basic level, many of the practical aspects of gas chromatography involve plumbing. The need for a leak-free and reliable flow path is essential in gas chromatography. Requirements of GC fittings are quite demanding relative to most remakeable plumbing fittings. They must be able to withstand use at high temperatures for long periods of time as well as repeated use over wide temperature swings, especially those in the GC oven. The least demanding GC connections are those outside the oven and not near an isothermal heated zone such a valve oven, inlet or detector.

Ferrules are used to provide a seal between a tube and a fixture. The fixture could be a union, a valve, a transfer line, or any other type of device to which one might want to attach a tube (or column). If the connection must only be made once and never change, then the tubes can be permanently attached through soldering, braising, cementing, etc. Then purpose of a ferrule is to make a connection that can be repeatedly undone and the redone as needed.

The easiest way to make a seal that can be re-made is to use some easily deformable material such as a rubber gasket. This is common in the home for such things as garden hoses. Unfortunately, such a connection cannot satisfy the special requirements of GCs. Gas chromatography has several unique characteristics that dictate unique requirements:

- Use of gases with very high diffusivities – these gases (He and H2) will find and take advantage of any, even minute, leak points

- Air can back diffuse through leaks, even against a pressure gradient

- Many of the detectors used in GC can detect air. Leaks that allow back diffusion of air then lead to raised detector baseline and increases drift.

- Many of the stationary phases used in GC are sensitive to air. Air leaks will lower column lifetime, increase column activity to polar compounds, and increase chemical noise in the signal. - Larger leaks will waste gas, some of which can be quite expensive (e.g., when using GC-grade He)

- Leaks along the sample flow path will vent sample (inlet side) or effluent (detector side) causing errors in the analysis

- In true mass flow control pneumatic circuits, leaks will cause errors in retention times (packed column inlets), or split ratios (split inlet total flow control).

The thing about leaks in GC is that they often vary considerably with temperature, vibration, and time. If leaks were constant, then some of the issues would go unnoticed because they would be corrected by calibration or would manifest as only constant offsets in the data.

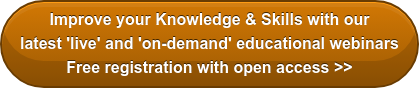

Metal ferrules come in two basic designs: one- and two-piece. Swagelok is the premier manufacturer of two-piece ferrule designs and has been around over 60 years. The two-ferrule design has some advantages (at a price premium) over single ferrule designs. Swagelok fittings are ubiquitous in the GC laboratory. In addition, Swagelok has infiltrated lab vernacular: It is common when making a ferrule connection of any type, to say that you are “swaging” the connecting. And when complete, that it “is properly swaged”.

Single-ferrule formats serve the same purpose as two-ferrule designs. As discussed below, one should match the ferrule type to the device, fixture, or fitting with which it will be used.

Hard metal ferrules (Figure 1) are only used with somewhat rigid but still deformable tubing. The seal is made over a relatively narrow region near the tip of the ferrule. The wedge design of the ferrule concentrates the tightening force from the nut or cap at the back of the ferrule to its tip. The tip compresses on the tube underneath. If the tube is a glass or fused-silica column, it would break. Metal or polymeric tubes, in contrast, will deform slightly, allowing the ferrule to “bite” into them permanently.

Metal ferrules can be used at high temperatures and can withstand wide temperature cycling, so they can be used for metal tubing connections in heated zones such as valve ovens and heated inlets and detectors. However, when used for extended periods at high temperatures, the ferrule can seize in the fitting.

Hard metal ferrules usually come in either brass or stainless steel. Stainless steel is usually used for connections in the sample flow path because it is more inert than brass. Outside the sample path, the safest approach is to use the same ferrule material as the fitting or fixture. One should never use a stainless ferrule with a brass fitting or fixture because steel is harder and can permanently damage the fitting. It is OK to use a brass ferrule with a stainless fitting if you are willing to cut off and replace the ferrule if it becomes marred.

In principle, metal ferrules have several attractive attributes summarized below.

- Metal has the least permeability to air

- Metal fittings can effectively seal against the largest pressure and temperature range

- Metal fittings are extremely rugged and can take a lot of abuse

- Metal fittings can be and remade many times (if not over tightened)

However, because they are hard, failure modes abound for standard metal fittings:

- Improper matching of ferrule and seat designs (avoid using generic ferrules)

- Over tightening and damage to the fitting or fixture

- Improper installation (shoving tubing into fitting too far and/or over tightening) can cause the end of the tubing to bulge in the fitting, making it difficult or impossible to remove.

- Seizing of the ferrule to the fitting after long periods at elevated temperature.

- Inability to seal over fine-lined striations in the metal tubing itself.

Figure 1: Examples of hard metal ferrules and uses. Swagelok fittings are popular for connecting gas feed lines to the GC. Valco fittings are typically associated with Valco gas sampling valves. These fitting types are not interchangeable.

To clarify the later bullet, based on the manufacturing process, the resulting rolled tubing stock (especially stainless steel) can have striations running done its length that allow air to sneak under the ferrule even though it is firmly swaged. Some individuals use sandpaper prior to swaging to remove or minimize the striations. The proper technique for this is to twist the sandpaper around the round axis of the tube to remove the ridges instead of running the sandpaper up and down the length of the tubing. The process of sanding leaves scratches itself; it is not an issue to leave concentric scratches around the tube but it is to have them in the same avis as the original striations.

A soft metal ferrule material (e.g., Siltite) has recently been introduced, which can be used for fused-silica column connections, and provides a nice combination of favorable features:

- They can deform slightly so that they seal with less force than is necessary with hard metal ferrules.

- They are soft enough to be used with fused-silica capillary columns.

- They are a little more forgiving of imperfect surfaces than hard metal ferrules.

- They have very low (or no) air permeability and can be used over the full range of GC

- temperatures.

- Unlike polymeric ferrules, soft metal ferrules do not shrink and therefore do not need periodic retightening.

- They are specially coat to reduce the risk of seizing in fittings.

Soft metal ferrules seize onto the column upon first use, so connections must be done with some care. I prefer to pre-tighten the ferrule onto an excess of column and then I trim the column to the appropriate length after the ferrule is set.

Figure 2: Examples of soft metal ferrules and applications. Pictures courtesy of Agilent Technologies, Inc.

Figure 2: Examples of soft metal ferrules and applications. Pictures courtesy of Agilent Technologies, Inc.

These soft metal ferrules are particularly suited for use when connecting to MS transfer lines or connections such as Capillary Flow Technology devices wherein one does not

typically need to trim the swaged column end regularly. Even though they deform slightly to accommodate some mismatch in fitting or fixture, soft metal ferrules should still be used with fittings that have the proper corresponding taper design. To this end, to benefit from using this style ferrule, one might have to buy replacement parts such as a new baseplate for the inlet or a special reverse nut for transfer line connections.

This blog article series is produced in collaboration with Dr Matthew S. Klee, internationally recognized for contributions to the theory and practice of gas chromatography. His experience in chemical, pharmaceutical and instrument companies spans over 30 years. During this time, Dr Klee’s work has focused on elucidation and practical demonstration of the many processes involved with GC analysis, with the ultimate goal of improving the ease of use of GC systems, ruggedness of methods and overall quality of results. If you have any questions about this article send them to techtips@sepscience.com