This study describes the performance features that enable Markes’ thermal desorption (TD) systems to be used for the GC–MS analysis of trace-level polychlorinated biphenyls (PCBs) in air.

Summary

Summary

The advantages of TD compared to conventional air monitoring methods for semi-volatiles are discussed, and it is shown how Markes’ innovative sample re-collection functionality facilitates method development by validating quantitative recovery of these challenging analytes all the way through the TD system. Other key results include high sensitivity (with limits of detection ranging from 0.022–0.054 ng, in line with independent studies), excellent linearities (mean R2 0.997), and high analytical precision (all RSDs below 2.5%).

Introduction

Polychlorinated biphenyls (PCBs) enter the environment from legacy sites for hazardous waste, from electrical equipment and construction materials, and by the improper disposal of consumer waste. Their tendency to persist in the environment and their known negative health effects has led to growing concern from regulators, which in turn has drawn attention to the need for reliable and practical analytical methods.

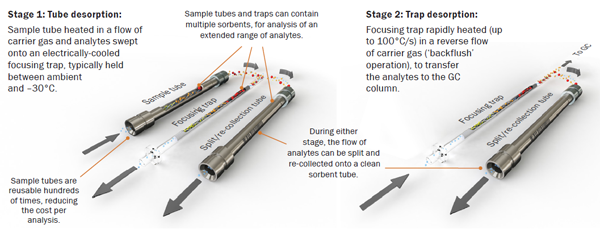

The technique of thermal desorption (TD), in conjunction with GC or GC–MS, has been used for several decades to overcome issues that arise for the monitoring of lower-boiling airborne volatile organic compounds (VOCs), and is now increasingly being applied to measurement of SVOCs, including compounds boiling up to n-C44 (b.p. 550 °C). As well as completely avoiding the need for manual solvent extraction/dilution and its associated disadvantages, TD offers a huge improvement in sensitivity because of the use of two-stage sample focusing, which allows smaller air volumes to be collected using portable battery-operated low-flow pumps.

In this study we describe the suitability of Markes’ TD100-xr™ 100-tube automated thermal desorber for monitoring airborne PCBs using this approach, by analysing a standard mix.

Background to thermal desorption

Thermal desorption is a versatile, solvent-free pre‑concentration technique for gas chromatography that is used to analyse volatile and semi-volatile organic compounds (VOCs and SVOCs) in air/gas, liquids and solids. By concentrating organic analytes present in air (or released from a sample) into a very small volume of carrier gas in a two-stage process (see below), TD maximises sensitivity for trace-level target compounds, helps to minimise interferences, and routinely allows analyte detection at the ppb level or below. It also greatly improves sample throughput, by combining sample preparation, desorption/extraction, pre-concentration and GC injection into a single automated process.

Results and discussion

Desorption efficiency and analyte recovery

Markes’ TD systems (manual and automated) are unique in allowing samples to be split and quantitatively re-collected onto a clean sorbent tube at the tube desorption and/or trap desorption stages. Re-collected samples can then be re-analysed for validation of analyte recovery as described in key international standards. Quantitative re-collection of samples also overcomes the ‘one-shot’ limitation of traditional TD systems, and allows samples to be re-analysed under the same or different conditions – for

example, with a selective detector or at a different split ratio to extend the dynamic range.

Conclusions

This study shows that Markes’ TD systems provide outstanding performance for a range of PCBs at typical environmental levels, with excellent system reproducibility (<4.5% RSD), linearity (R2 ≥0.997) and MDLs below 0.06 ng. The high desorption efficiencies obtained (>96% relative to PCB-28) are also an important finding, because they demonstrate the robustness of Markes’ automated thermal desorption systems as a practical alternative to manual solvent extraction for monitoring these important high boiling pollutants in ambient air.