Here we continue the discussion of inlet liners with a focus on liner outer diameter. It is important to realize that correct liner choice is most critical for:

- Capillary column analyses

- Splitless injections

- Labile samples

- Samples with wide range of analyte volatilities

- Small bore columns

- Slow sample introduction techniques that introduce samples that are gases at room conditions

For some methods, any old liner will do. For others, especially those with multiple aspects of the above list, only a limited number of choices will provide the required performance. When choosing a liner, one of the parameters to consider is its outer diameter.

The maximum outer diameter of a liner is limited by the inner diameter of the specific inlet weldment for which it is designed to be used. Tight liners are best for some applications and looser liners best for others. No one liner is best for everything, even though a compromise in dimensions can still work for a given application.

With packed column inlets, all of the flow through the inlet goes through the liner into the column. Any sample vapors that are allowed to diffuse between the liner and the inlet weldment (stagnant space) can lead to no good (not that it causes an observable problem; just that it can). So a tight liner is best for packed column (“direct”) inlets. The liner should extend to the bottom of the inlet and restrict sample exposure to any metal at the base.

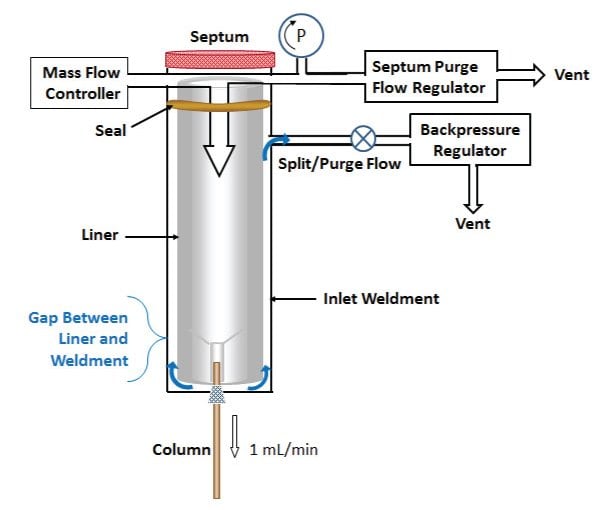

In all cases with split/splitless and PTV inlets, there must be enough space between the liner and the inlet weldment for split/purge flow to flow without restriction, as illustrated in Figure 1. If the space is too narrow, there can be problems.

Figure 1: Typical split/splitless inlet pneumatic design. A mass flow controller supplies a total flow to the inlet which is then divided between column, purge, and split vent flows. Even though liners that are tight in the inlet weldment may be best for splitless injections, they can cause inlet pressure to exceed setpoint with higher split vent flow rates.

In inlet pneumatic designs that are backpressure controlled, as in Figure 1, a total flow is supplied to the inlet with a mass flow controller. That total flow is then split into three potential paths: split, septum purge, and column flows. In the case of splitless injection, there is no spit (purge) flow during injection, but there is as soon as the purge delay time has expired.

For splitless injections, it is important to minimize the volume outside the liner, which means that the ideal splitless liner is fairly tight in the inlet weldment. This tightness, although not problematic for purge flow rates of 25-50 mL/min once the purge turns ON, can be too much if the same liner were to be used for split injections. With split injections where the split flow may be several hundred mL/min, the resistance of tight liners can lead to inlet pressures higher than the setpoint. This is most likely to be observed with larger diameter columns (e.g., 530 µm i.d.) and higher inlet temperatures (when gases are most viscous and potential narrowing of the gap further due to expansion of the weldment from the heat). Large i.d. columns run at low head pressures and higher flow rates to start with. So even low split ratios can require split flows of several hundred mL/min, which could create a significant backpressure in the inlet with pneumatic designs that supply a constant total flow to the inlet. In contrast, for forward-pressure controlled inlets, the pressure will remain at the setpoint, but the added resistance around the liner will cause split/purge flow to decrease below setpoint. The major point being: what is best for splitless injections is not what is best for split injections.

For split injections, residence times of samples in the liner are fairly low and the likelihood that sample vapors that have migrated outside the liner will return to the entrance of the column is low, so it is not as important to minimize extra-liner volume as it is with splitless injections. Split flows are also potentially higher than splitless purge flows, so any restriction from a tight liner could end up with a more dramatic increase in head pressure. Therefore, for split injections, a looser liner is preferred. We are only talking about one or two tenths of millimeters difference between “tight” and “loose”. Too loose of a liner (a big gap) would present other issues.

The way I empirically tell the difference between splitless and split liners is by wiggling them while I install them. A proper splitless liner will have very little play back and forth as it is installed, even when just pushing in the first couple of millimeters into the weldment. A proper split liner will have approximately twice as much play (for a given insertion depth). Some manufacturers disclose the outer dimensions of their liners and some do not. When choosing between two liners in the drawer, the empirical wiggle approach is helpful in differentiating them if a micrometer is not available.

Due to the expense of manufacturing multiple liner dimensions and the lack of stock tubing that matches well with the inner diameter of inlet weldments, many manufacturers restrict their offerings and market liners that are “general purpose”, with claims that they work well for everything. Inevitably, these are loose liners. The tighter splitless liners often require more expensive stock glass or intensive manufacturing (e.g., grinding to tolerance). Therefore these “all purpose” liners are more suited to split injections than splitless from an outside diameter standpoint.

In the next part we continue the liner discussion with a focus on internal volume.

This blog article series is produced in collaboration with Dr Matthew S. Klee, internationally recognized for contributions to the theory and practice of gas chromatography. His experience in chemical, pharmaceutical and instrument companies spans over 30 years. During this time, Dr Klee’s work has focused on elucidation and practical demonstration of the many processes involved with GC analysis, with the ultimate goal of improving the ease of use of GC systems, ruggedness of methods and overall quality of results. If you have any questions about this article send them to techtips@sepscience.com