A reader asked me when it is appropriate or necessary to premix mobile phases when on-line mixing is available. For example, if a gradient is run from 95/5 buffer/organic (5% B) to 5/95 buffer/organic (95% B), should one bottle contain 95% buffer and the other 5% buffer in the organic solvent, or should one bottle contain buffer and the other the organic? In either case, the HPLC system can be programmed to give exactly the same mobile phase composition.

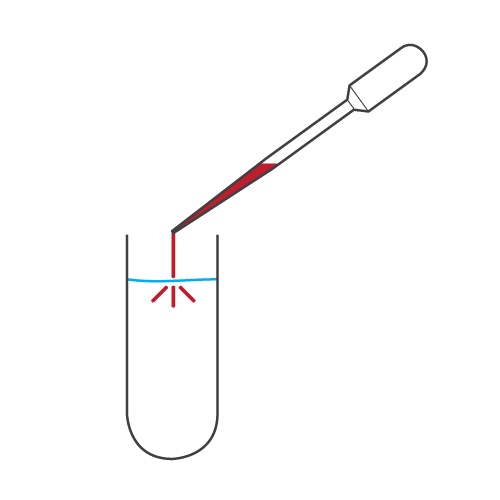

From the standpoint of extra work and the possibility of introducing errors, the use of two reservoirs of pure solvents makes sense, so this is what most workers prefer. There are at least three cases where premixing makes sense. The first case has to do with buffer solubility. This is especially a problem when phosphate buffer is used and acetonitrile (ACN) is the organic solvent. Phosphate has rather poor solubility in ACN. For example, 10 mM is about the limit of solubility of phosphate in 80% ACN, but even this can be a problem under the right circumstances. For example, if 10 mM phosphate is mixed with 100% ACN on-line to obtain a 30/70 10 mM phosphate/ACN solution, precipitation can occur at the interface of the two solvents inside the mixer, because 100% ACN is present at the interface with 10 mM phosphate. If the two solutions were mixed by hand in bulk, no problems would occur and the resulting solution could be used reliably. Such on-line mixing problems are very instrument-dependent, so mixtures that are fine on one make and model of HPLC may have problems on another. I have a simple test to check for potential problems. Place a few mL of buffer in a test tube and add the organic drop-wise, then try the same experiment by adding buffer to a tube containing the organic solvent. Watch for precipitation or cloudiness at the interface, suggesting localized precipitation. If this is observed, I recommend premixing the solvents.

A second reason to use premixing is to get quieter baselines. The design and application of on-line mixers is a balance between keeping the volume small and obtaining adequate mixing. As a result, with the proper visualization techniques, you can always see a little waviness of the baseline resulting from incomplete mixing. This isn’t a problem with most UV applications, but for refractive index (RI) detectors, premixing is required, because any inhomogeneity of the mobile phase will be reflected in baseline fluctuations. In some cases for UV methods operating at the limits of the detector, a quieter baseline can be obtained if isocratic mobile phases are premixed or gradient mobile phases are partially mixed (for example, 5% B in A and 5% A in B).

The third reason to use premixing is if the separation is sensitive to the concentration of buffer salt. For example, a gradient from 25 mM phosphate to methanol (MeOH) will be a reverse-gradient in phosphate concentration if the buffer is placed in the A-reservoir and MeOH in B. If it were desired to keep the buffer concentration constant, buffer could be added to B so that no change in buffer concentration took place during the gradient. This approach is seldom needed in reversed-phase HPLC, and is inconvenient, so it seldom is used.

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com